Mastering the Workshop: A Detailed Guide to Must-Have Woodworking Tools

In the intricate dance of woodworking, every tool plays a pivotal role, akin to an artist's brush strokes on canvas. Each piece of wood, with its unique grain and texture, is a blank slate waiting to be transformed by the skilled hands of a craftsman. This guide delves deep into the essential tools that form the backbone of a woodworker's arsenal, ensuring precision, efficiency, and the pure joy of creation.

Insightful Woodworking Tool Essentials:

- Invest in Quality: High-quality tools not only last longer but make your work easier and more precise.

- Tool Versatility: Tools that perform multiple functions save space and offer better value.

- Ergonomic Design: Tools designed for comfort reduce strain and increase control.

- Simplify Tasks with the Right Tools: The right tool can turn a complex project into a manageable and enjoyable one.

Detailed Exploration of Each Essential Woodworking Tool:

- Table Saw

- Core Tool: The table saw is the quintessential tool for any woodshop, indispensable for its versatility in making straight, angled, or beveled cuts with precision.

- Benefits: Offers unmatched accuracy with minimal waste, ideal for handling large wood panels.

- Must-Have Features: Look for saws that offer easy adjustability, robust power, and enhanced safety features like riving knives and blade guards.

- Pro Tip: Opt for a table saw with a reliable fence system for consistently straight cuts.

- Miter Saw

- Precision Cuts Made Simple: A miter saw is crucial for precise angled and crosscuts, making it a favorite for framing and molding projects.

- Key Features: Safety guards, precise angle adjustments, and a robust motor for handling thick wood without bogging down.

- Special Considerations: For optimal use, choose a saw with a sliding feature to extend the cutting width for larger pieces.

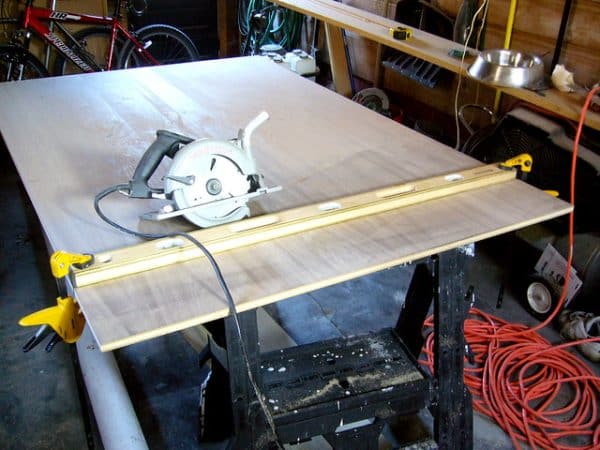

- Circular Saw

- Versatility on the Go: Known for its portability, the circular saw is a go-to for making quick onsite cuts.

- Benefits: Capable of rip cuts, crosscuts, and beveled edges, its adaptability makes it essential for both rough construction and fine detail work.

- Choosing the Right Saw: Prioritize models with sturdy bases, electric brakes, and adjustable depth settings to handle a variety of wood thicknesses.

- Jigsaw

- For Intricate and Curved Cuts: The jigsaw excels at detailed and curved cutting, ideal for patterns and custom decorations.

- Features to Look For: A tool-less blade change system, variable speed controls, and an orbital setting for aggressive cutting actions.

- User Tips: For cleaner cuts, select blades that match the type of wood and complexity of the cut you’re making.

- Band Saw

- Master of Curves and Thickness: Perfect for detailed scrollwork and resawing thick lumber, the band saw is a powerhouse for precision.

- Essential Features: Large throat for big pieces, variable speed settings, and a sturdy table for stability.

- Optimal Use: Regular blade maintenance and correct tensioning are crucial for achieving smooth, straight cuts.

- Router

- The Detailer’s Dream: Ideal for adding decorative flairs, dovetails, and profiles to edges.

- Key Features: Variable speeds, a plunge base for interior cuts, and a fixed base for edge work.

- Expert Advice: Use sharp, high-quality bits and practice on scrap pieces to perfect your technique before tackling the main project.

- Planer

- Achieving Uniform Thickness: Essential for smoothing rough lumber and achieving uniform thickness across your workpiece.

- Types of Planers: From handheld to benchtop models, choose based on the scale of your projects and workspace constraints.

- Planer Best Practices: Ensure the blades are sharp and the feed rate is appropriate to prevent gouging and snipe.

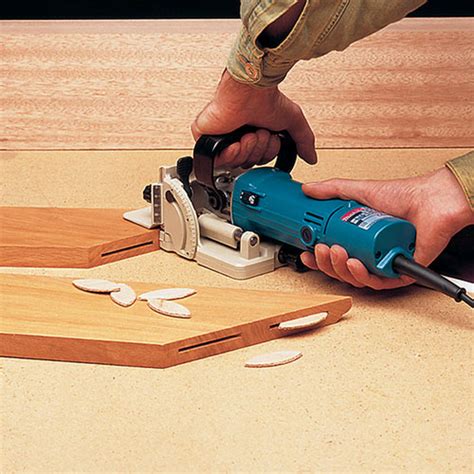

- Joiner

- For Seamless Joints: A joiner is invaluable for creating perfect seams and aligning boards with precision.

- Choosing a Joiner: Look for models with adjustable fences and depth settings to handle different board thicknesses and joint types.

- Practical Use: Regular calibration ensures consistent accuracy in your joints, enhancing the structural integrity of your projects.

- Drill Press

- Precision Drilling at Its Best: Offers more stability and accuracy than handheld drills, perfect for repetitive holes and precise depths.

- Features to Consider: An adjustable table, variable speed controls, and depth stops for consistent results.

- Maintenance Tips: Keep the drill press clean and lubricated, and regularly check for wear on belts and bearings.

- Random Orbital Sander

- The Finishing Touch: Essential for achieving a smooth, flawless finish on wood surfaces.

- What to Look For: Variable speed settings, dust collection systems, and an ergonomic design for comfort during extended use.

- Sanding Tips: Always start with a coarser grit and work your way up to finer grits for a glass-smooth finish.

Conclusion: Crafting with Confidence

Arming yourself with these fundamental tools is like setting the foundation of a building—essential for the integrity and quality of all that follows. Each tool not only serves a specific purpose but also brings you closer to realizing the vision of your unique woodworking projects. Remember, in the realm of woodworking, your tools are your best allies, fostering both creativity and craftsmanship in every piece you create.